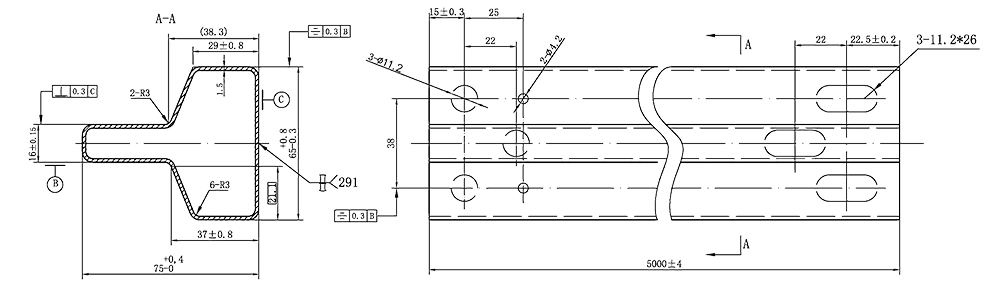

OTrilho guia oco de extremidade fechadaé um trilho de guia de elevador especializado com uma estrutura oca retangular comextremidades seladas (fechadas). Projetado para atender às demandas de ambientes de poços mais limpos e desempenho otimizado de resistência ao peso, esse tipo de trilho é amplamente utilizado em sistemas de elevadores modernos que exigem durabilidade e facilidade de instalação.

Ao contrário dos trilhos ocos padrão com extremidades abertas, o design de extremidade fechada evita que poeira, umidade e materiais estranhos entrem na cavidade do trilho, tornando-o especialmente adequado para aplicações de alta precisão, sensíveis à poeira ou com manutenção restrita a longo prazo.

Trilhos de guia ocos fechados são projetados especificamente para aumentar a proteção ambiental e a confiabilidade operacional a longo prazo em condições industriais exigentes. Ao selar as extremidades do perfil oco, esse design efetivamente impede que poeira, detritos, umidade e outros contaminantes entrem na cavidade interna do trilho. Como resultado, o risco de corrosão interna, acúmulo de partículas abrasivas e contaminação por lubrificante é significativamente reduzido, mesmo em ambientes com muita poeira, úmidos ou quimicamente agressivos.

Essa estrutura fechada contribui diretamente para a maior confiabilidade ao longo da vida útil do sistema de guia. Com menos contaminantes afetando superfícies internas e zonas de suporte, as taxas de desgaste são mais consistentes e a degradação inesperada do desempenho é minimizada. Portanto, trilhos de guia ocos fechados requerem menos limpeza e manutenção, mantendo uma orientação linear estável e integridade dimensional por períodos operacionais prolongados. Essas características as tornam particularmente adequadas para aplicações onde exposição ambiental, requisitos de tempo de funcionamento e durabilidade a longo prazo são considerações críticas.

De acordo com as normas internacionais: ISO7465:2007; ISO630: 2021. De acordo com os padrões internacionais, realize testes abrangentes de matérias-primas com base na certificação de materiais fornecida pelos fornecedores para garantir que a qualidade de cada lote de matérias-primas atenda aos requisitos.

Configure duas linhas de produção automatizadas de trilhos-guia. O equipamento deve garantir que os itens produzidos cumpram ou excedam os requisitos do cliente, mantendo a estabilidade da retidão, distorção e rugosidade da superfície

Dados os rigorosos requisitos de retidão e torção nas guias de grau BE, foram implementados equipamentos especializados de endireitamento automático e correção de torção, juntamente com sistemas avançados de detecção. A retidão é mantida dentro de 0,5 mm, enquanto a torção é controlada dentro de 30' por metro

O conceito de serviço de "cliente em primeiro lugar" afirma que, independentemente de onde nossos serviços são prestados - seja dentro da empresa, no local de trabalho do cliente, no canteiro de obras ou durante o transporte - nosso objetivo principal continua sendo satisfazer o cliente